NACHTMANN & Sustainability

Our responsibility is crystal clear

NACHTMANN is synonymous with high-quality, robust products of enduring distinction.

Glass production, particularly the melting process, is an extremely energy-intensive operation. We are absolutely clear about our responsibility to design our activities for maximum sustainability and our aim to improve our energy efficiency on an ongoing basis.

At NACHTMANN, sustainability starts with careful selection of raw materials. With few exceptions, the quartz sand, metal oxide, lime, and potash we use are sourced from our own region and have only a short distance to travel.

NACHTMANN

Our Glassware

NACHTMANN & Sustainability

Our tip for fans of sustainable products

Our bowls with matching silicone lid are the long-lasting alternative to plastic wrap, BPA-free and dishwasher-safe. Perfect for perserving the freshness and flavors of food for a long time.

Sustainability

Systematic energy management

NACHTMANN’s works in Bavaria are cutting-edge glass factories in line with the state of the art. Our first works gained ISO 14001 certification for its environmental management system as early as 2001; the first ISO 50001 energy management system certification was awarded to our company in 2010.

Today, certified environmental and energy management systems are in place at all our manufacturing locations.

NACHTMANN

Our factories

- Energy-saving projects include: compressed air, burner technology, energy efficient drives, LED lighting, waste heat recovery, water saving measures

- Implemented environment certificates ISO 14001: 2015 and ISO 50001: 2011.

- Main raw materials are locally sourced e.g. quartz sand from Hirschau (short transport routes)

- Substitution of hazardous substances with more environmentally friendly options.

NACHTMANN & Sustainability

Our road to more energy efficiency

Our Amberg and Weiden locations are increasingly turning to renewable energy sources; our rooftop photovoltaic system at the Weiden production facility will go into operation, and we will use the thermal energy from melting tank exhaust gases to generate electricity.

We continue to take steps along the road to greater energy efficiency.

NACHTMANN

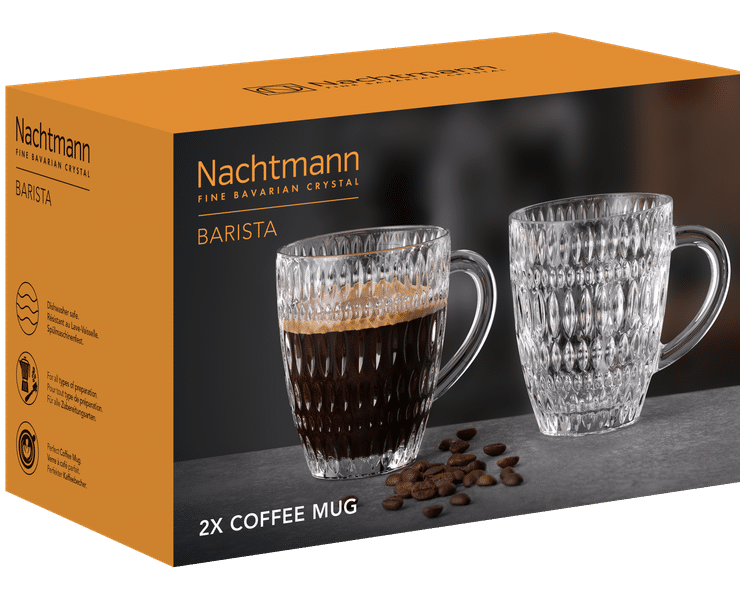

Our packaging

Both our packaging and products are recyclable.

Please dispose of them in the designated waste bins at the end of their life.